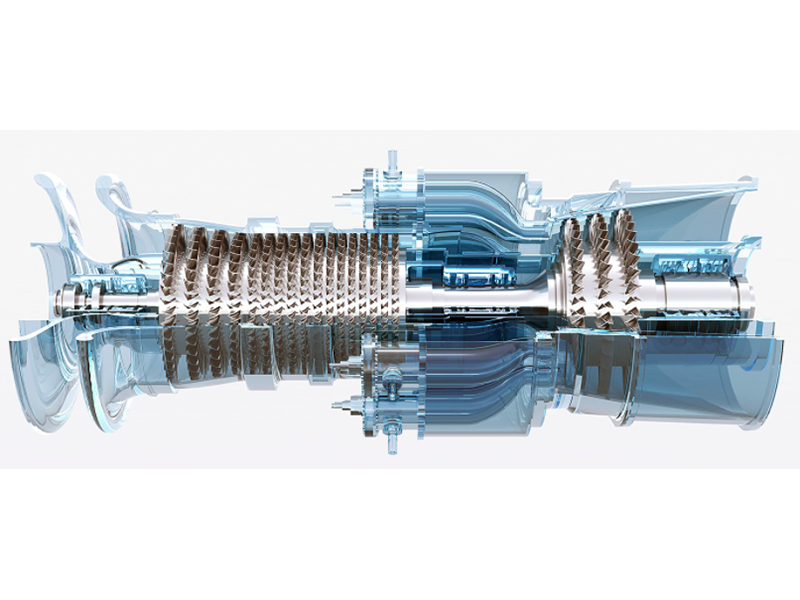

We have mature gas turbine repair experience, can provide customers with refurbishment, maintenance, and product repair services to improve the service life of the gas turbine, and troubleshooting, our company has a variety of gas turbine sales cooperation in China, we can provide customers with repair parts quickly, shorten the repair time. We will give full consideration to the operating environment, process characteristics and customer needs, and ensure the safe and reliable operation of the equipment.

Dongturbo Electric Company Limited offers repair and field service to various equipment users, from aircraft engine to power plant equipment , including heavy duty & light gas turbine, steam turbine and generator. We are continuously focusing on high temperature alloy component repair, upgrade and modification, repair on fuel nozzle, bearing, valve and other accessory parts .

Supported by Global Technology Resources , We are providing high quality, fast-turnaround service result to customer.

Gas turbine power station installation, commissioning, maintenance and after-sales service work mainly by the company technical staff, can be independently completed a variety of models of gas turbine overhaul and minor repairs.

Gas turbine overhaul: gas turbine intake and exhaust inspection; intake adjustable guide vane (IGV) examination; compressor and static blade inspection; turbine rotating blades and stator blades inspection; rotor check; front bearings and after bearings inspection; gas turbine cylinder inspection; combustion chamber and the inner cylinder inspection; clutch inspection; shafting alignment; gas turbine commissioning period of dynamic balance.

Regular inspection of auxiliary system: turning gear inspection; main, auxiliary and emergency lube oil pump inspection; jacking oil pump inspection; exhaust fan check; tank and oil filter check and clean; lubricating oil pipe and gas pipe inspection.

Generator overhaul: extract and check out generator rotor; inspection for front and after part of generator bearings; generator stator check; generator electrical preventive test; generator transformer group protection equipment inspection and verification; generator transformer group control signal loop check and transmission test and so on.

Long-time operation and maintenance service

Minor Inspection and miscellaneous parts and component consumable

Major Inspection and spare parts supply

Scope of Major Inspection for E Class Gas Turbine

| Equipment | Scope Of Work |

| Gas Turbine Plant, Air Intake System and Exhaust Channel | |

| Visual inspection of the silencer, compressor washing system, outlet diffuser, compensator and casing of the compensator. | |

| NDT of the case lining | |

| Compressor | |

| Case | Verification and control of the assembled impeller inlet guide vane, visual inspection, removal of defects, as required. |

| Rotor | Visual inspection of the first stages of rotating blades with an endoscope, as required. |

| Cleaning, visual inspection and nondestructive testing of rotating blades | |

| Removal of rotating blades, restoration of coating of rotating blades, reassembly.(Excluding compressor coating) | |

| Shaft seal | Visual inspection, replacement of sealing rings, as required. |

| Turbine | |

| Casing | Removal of the top half of the center case, visual inspection, correction of the center case defects, as required. |

| Removal of the top half of the guide vane carrier, visual inspection, nondestructive testing, and correction of carrier defects, as required. | |

| Removal of the top half of the outlet body, visual inspection, removal of outlet body defects, as required. | |

| Removal of stage 1-2 guide vanes, installation of guide vanes with restored coating on stages 1-2. | |

| Replacement of stage 3-4 guide vanes, as required according to results of the visual and nondestructive testing. | |

| Replacement of sealing ring segments of turbine stages 1 – 4, as required according to results of visual inspection and nondestructive testing. | |

| Reassembly of the turbine, alignment of the flow path, center case, outlet body and exhaust diffuser. | |

| Rotor | Removal of all stage 1-3 rotating blades, reassembly of stage 1-3 rotating blades with restored coating. |

| Replacement of stage 4 rotating blades, as required according to results of visual inspection and nondestructive testing. | |

| Shaft seal | Inspection of sealing bands, replacement, as required. |

| Rotor | |

| Control of radial and axial beating of the rotor, measurement of radial gaps of rotating blades. | |

| Rotor balancing, as required. | |

| Bearings | |

| Checking bearing cases and sealing rings for oil leakage. | |

| Elimination of defects of rotor crank-shaft necks and bearing babbit wear-out, fatigue bands, lines, scratches and cracks, improvement of the surface, babbit adhesion control, as required, replacement, checking centrifugal throwers of bearings according to results of visual and nondestructive control. | |

| Coupling | |

| Removal of coupling protective shroud, checking technical parameters. | |

| Coupling disassembly: gas turbine – countershaft, countershaft – generator, checking coupling bolt extensions, control of radial and end beating, shaft alignment. | |

| Reassembly of coupling protective shroud. | |

| Shaft Turning Gear | |

| Visual inspection, checking oil feed. | |

| Opening of the shaft turning case, visual inspection, elimination of defects, as required, reassembly of the shaft turning case. | |

| Compressor Diffuser | |

| Visual inspection, elimination of defects, as required. | |

| Inner Case | |

| Visual inspection and superficial nondestructive testing (for cracks). | |

| Repair, including annealing, as required (included into the Contract cost)Note : Onsite minor repair | |

| Combustion Chambers | |

| Elimination of fuel, air, water pipeline defects according to results of the visual inspection. | |

| Removal of combustion chambers, removal of combustion chamber covers, cleaning and control of bolt extension, replacement, as required. Removal of the refractory liner. | |

| Elimination of gas distributer defects in case of any malfunction revealed or with account of condition of the gas turbine according to results of visual inspection and nondestructive testing. | |

| Repair of the bottom and outer case of the refractory liner, combustion chamber body, sealing ring for tiles, welds, cooling air rings, hatch inserts, as required according to results of the visual inspection.Note : Onsite minor repair | |

| Repair of base structures and guides of internal assemblies with account of their condition, operability control of the secondary air ring, as required according to results of the nondestructive testing.Note : Onsite minor repair | |

| Reassembly and installation of the combustion chambers. | |

| Thermal screens | Visual inspection for cracks, breaks, traces of erosion; replacement of thermal screen tiles, as required in accordance with the list of corrective actions. |

| Faucet | |

| Visual inspection and superficial nondestructive testing (for cracks). | |

| Repair, including annealing (included into the contract cost), as required.Note : Onsite minor repair | |

| Burners | |

| Visual inspection. | |

| Removal, cleaning and nondestructive testing of the burners, axial/diagonal swirlers, igniters, repair, as required.Note : Onsite minor repair | |

| Reassembly. | |

| Outlet Body | |

| Visual inspection. | |

| Nondestructive testing for cracks (weld testing for cracks), repair, as required Note : Onsite minor repair | |

| Lubricating Oil Feed | |

| Lube oil tank | Visual inspection. |

| Oil separation and analysis, as required. | |

| Main and auxiliary oil pumps | Removal of pumps, checking bearings, seals, shafts and impeller wheels, repair, as required. |

| Pump of the rotor hydraulic hoist, emergency pump, exhauster | Removal of pumps/fans, checking bearings, shafts and impeller wheels, repair, as required. |

| Oil filters | Filter checking and cleaning. |

| Motors | Checking electrical and mechanical connections. |

| Checking operation noise level. | |

| Disabling, disconnection and removal of motors, checking bearings, repair, as required. | |

| Pipelines of Lifting and Lubricating Oil | |

| Visual inspection of pipelines, flange connections and base structures, repair, as required. | |

| Commissioning following the Planned Outage | |

| Control of set values of control, adjustment and protective devices and instruments. | |

Supply for new capital parts(rotating blade, guide vane and etc)

Refurbishment works(Mixing chamber repair, inner casing repair, refurbishment of blade and vane)