For the first time worldwide, in a demonstration conducted through the "Gas Turbine Alternative Fuel" project at the Net Zero Technology Center (NZTC), Siemens Energy successfully operated an SGT-A35 gas turbine using methanol. Recent demonstration tests have shown a reduction of up to 80% in nitrogen oxides.

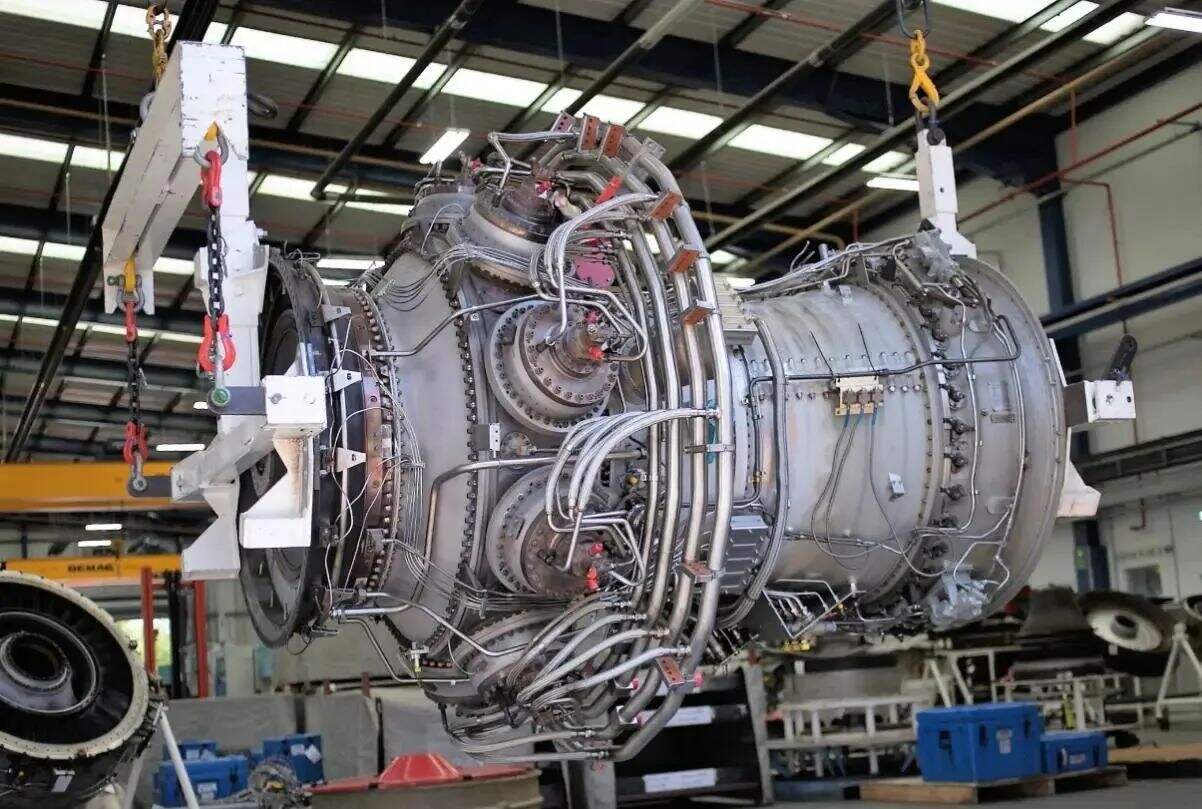

The SGT-A35 was launched by Rolls Royce in the 1970s to provide power generation and mechanical drive applications for the oil and gas industry.

SGT-A35 (Industrial RB211)

This demonstration will take place at the Aberdeen facility owned by RWG (a specialist in gas turbine maintenance, repair, and overhaul). This facility has been specially renovated for this pilot project.

Siemens Energy has used 3D printing technology to manufacture the components required for methanol fuel conversion, although this only represents what the company calls "minor modifications".

For the first time worldwide, Siemens Energy demonstrated a low-power SGT-A20 gas turbine operating with biomethanol in 2023, demonstrating a reduction of up to 75% in carbon dioxide emissions compared to traditional fuels. Recent demonstration tests have shown a reduction of up to 80% in nitrogen oxides.

NZTC project manager Charlie Booth said, "This is a key milestone and great achievement for the 'Gas Turbine Alternative Fuel' project, which can only be achieved through excellent collaboration with the government and industry. The unique characteristics of methanol make it an excellent modifiable, low-carbon alternative fuel, and we are able to showcase the opportunities that exist in adjusting existing infrastructure to achieve our net zero goals and energy demand, which is fantastic. I want to express my gratitude to all project participants who have made this possible.

Darren Davidson, Vice President of Siemens Energy UK and Ireland, said, "This is another important step in our transition to a clean energy future in the North Sea. The successful operation of this gas turbine on methanol marks a critical moment in our journey towards sustainable energy. This achievement not only highlights the versatility and adaptability of our turbine, but also emphasizes the practical steps we can take to reduce carbon dioxide emissions in industries that are difficult to decarbonize. I am proud of the role our team played in our collaboration and achieved this goal.