We provide power plant efficiency upgrades,equipment retrofits,and waste heat recovery and utilization. Our services are designed to help power plants improve efficiency,reduce energy consumption and operating costs. We have a team of experienced engineers who are experts in the field of power plant engineering and are able to provide comprehensive solutions to your needs.

Our efficiency upgrade services include retrofitting existing power plants with new advanced technologies,such as modifying existing equipment and installing new high-efficiency equipment to improve the overall performance of the plant. We also offer equipment modification services,such as retrofitting boiler systems,turbine systems,and generator systems to improve efficiency and reduce maintenance costs.

Steam turbine retrofitting can make full use of productivity and mechanical raw materials, and can help producers to complete relevant production needs in a timely and effective manner. People can use steam turbine retrofitting to get help in many aspects, such as providing energy for factory production needs, using existing technical conditions to carry out retrofitting of steam turbine, improving use efficiency, reducing energy consumption, bringing more economic and social benefits to enterprises or individuals, and promoting rapid development of productivity and society.

(1) Pre-retrofit and post-retrofit technical data comparison

| item | unit | before retrofit | after retrofit | |

| supplier | LMZ of Former USSR | |||

| model of the unit | K-500-23.5-4 | N550-23.54/540/540 | ||

| start time of operation | 1998 | 2016 | ||

| rated/max. output | MW | 590/550 | 550/598 | |

| design features | impulse | reaction | ||

| speed | r/min | 3000 | 3000 | |

| main steam | pressure | MPa | 23.54 | 23.54 |

| temperature | ℃ | 540 | 540 | |

| reheat steam | pressure | MPa | 3.51 | 3.50 |

| temperature | ℃ | 540 | 540 | |

| efficiency of HP casing | % | 83 | 89 | |

| efficiency of IP casing | % | 90 | 94 | |

| Efficiency of LP casing | % | 72.5 | 87 | |

| back pressure | kPa | 4.27 / 5.44 | 4.27 / 5.44 | |

| heater | 8 | 8 | ||

| result of heat rate improvement | kJ/kWh | standard | 550 reduced by appr. 550 | |

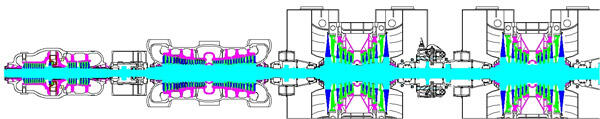

(2) Scope of replacement for the retrofit of steam path components

The scope of replacement for the retrofit of steam path components is illustrated in color as below:

(3) Execution of the retrofit project

To check and accept the efficiency of casings and level of heat rate in strict conformity with the ITP specification of ASME PTC6-1996.

Lead time: 12---15 months

Period of retrofit activities at site: 90---100 days.

(4) Result of retrofit

The heat rate of steam turbine is to decrease appr. 550KJ/KWh. The coal consumption is to decrease 22g/kwh.

Annual standard coal saving: approximately 60,000.- tons (based on the annual usage rate of 5000 hours)

Annual reduction of CO2 emission: appr. 150,000.- tons (based on the annual usage rate of 5000 hours)

Annual increase of power generation: 250 million KWh (based on the annual usage rate of 5000 hours)

Payback period of investment: ~ 2 years.

(1) Pre-retrofit and post-retrofit technical data comparison

| item | unit | before retrofit | after retrofit | |

| supplier | Kharkov of former USSR | |||

| model of the unit | K-320-23.5-4 | N340-23.54/540/540 | ||

| start time of operation | 1994.3 | 2008.12 | ||

| rated/max. ouput | MW | 320/335 | 340/354 | |

| speed | r/min | 3000 | 3000 | |

| main steam | pressure | MPa | 23.54 | 23.54 |

| temperature | ℃ | 540 | 540 | |

| reheat steam | pressure | MPa | 3.69 | 3.71 |

| temperature | ℃ | 540 | 540 | |

| extraction steam | rated | t/h | / | 50 |

| max. | t/h | / | 70 | |

| extraction steam pressure | MPa | / | 0.9 | |

| back pressure | kPa | 4.8 | 4.8 | |

| heater | 8 | 8 | ||

| result of heat rate improvement | kJ/kWh | standard | 640 reduced by appr. 640 | |

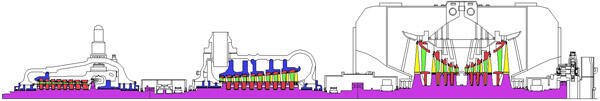

(2) Scope of replacement for the retrofit of steam path components

The scope of replacement for the retrofit of steam path components is illustrated in color as below:

(3) Execution of the retrofit project

To check and accept the efficiency of casings and level of heat rate in strict conformity with the ITP specification of ASME PTC6-1996.

Lead time: 12---15 months

Period of retrofit activities at site: 70---90 days.

(4) Result of retrofit

The heat rate of steam turbine is to decrease appr. 640KJ/KWh. The coal consumption is to decrease 25g/kwh.

Annual standard coal saving: approximately 40,000.- tons (based on the annual usage rate of 5000 hours)

Annual reduction of CO2 emission: appr. 108,000.- tons (based on the annual usage rate of 5000 hours)

Annual increase of power generation: 100 million KWh (based on the annual usage rate of 5000 hours)

Payback period of investment: 2~3 years.

(1)Pre-retrofit and post-retrofit technical data comparison

| item | unit | before retrofit | after retrofit | |

| supplier | LMZ of former USSR | |||

| model of the unit | K300-170-3 | N320-16.2/540/540 | ||

| start time of operation | 1996 | 2011.3 | ||

| rated/max. output | MW | 300/320 | 320/336 | |

| speed | r/min | 3000 | 3000 | |

| main steam | pressure | MPa | 16.2 | 16.2 |

| temperature | ℃ | 540 | 540 | |

| reheat steam | pressure | MPa | 3.53 | 3.57 |

| temperature | ℃ | 540 | 540 | |

| extraction steam | rated | t/h | / | 350 |

| max. | t/h | / | / | |

| extraction steam pressure | MPa | / | / | |

| back pressure | kPa | 5.6 | 5.6 | |

| heater | 8 | 8 | ||

| result of heat rate improvement | KJ/kWh | standard | 410 reduced by appr. 410 | |

(2) Scope of replacement for the retrofit of steam path components

The scope of replacement for the retrofit of steam path components is illustrated in color as below:

(3) Execution of the retrofit project

To check and accept the efficiency of casings and level of heat rate in strict conformity with the ITP specification of ASME PTC6-1996.

Lead time: 11---12 months

Period of retrofit activities at site: about 70 days.

(4) Result of retrofit

The heat rate of steam turbine is to decrease appr. 410KJ/KWh. The coal consumption is to decrease 16g/kwh.

Annual standard coal saving: approximately 25,600.- tons (based on the annual usage rate of 5000 hours)

Annual reduction of CO2 emission: appr. 69,000.- tons (based on the annual usage rate of 5000 hours)

Annual increase of power generation: 100 million KWh (based on the annual usage rate of 5000 hours)

Payback period of investment: 2~3 years.

(1) Pre-retrofit and post-retrofit technical data comparison

| item | unit | before retrofit | after retrofit | |

| supplier | LMZ of former USSR | |||

| model of the unit | K215-130-1 | C228-12.75/0.245/540/540 | ||

| start time of operation | 1989.10In year 2000, Siemens performed the retrofit for the LP steam path of the LP casing | 2008.11Quansiwei performed the retrofit for the HP & IP steam path of the HP & IP casing | ||

| output | rated | MW | 219.9 | 228 |

| max. | MW | 226 | 235 | |

| speed | r/min | 3000 | 3000 | |

| main steam | pressure | MPa | 12.75 | 12.75 |

| temperature | ℃ | 540 | 540 | |

| reheat steam | pressure | MPa | 2.40 | 2.11 |

| temperature | ℃ | 540 | 540 | |

| extraction steam | rated | t/h | / | 200 |

| max. | t/h | / | 340 | |

| extraction steam pressure | MPa | / | 0.245 | |

| back pressure | kPa | 5.0 | 5.0 | |

| heater | 8 | 8 | ||

| result of heat rate improvement | KJ/kWh | standard | 243 reduced by appr. 243 | |

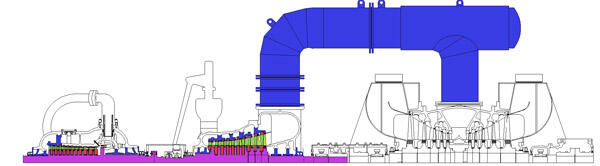

(2) Scope of replacement for the retrofit of steam path components

The scope of replacement for the retrofit of steam path components is illustrated in color as below:

(3) Execution of the retrofit project

To check and accept the efficiency of casings and level of heat rate in strict conformity with the ITP specification of ASME PTC6-1996.

Lead time: 9---11 months

Period of retrofit activities at site: about 55 days.

(4) Result of retrofit

The heat rate of steam turbine is to decrease appr. 243KJ/KWh. The coal consumption is to decrease 10.4g/kwh.

Annual standard coal saving: approximately11,000.- tons (based on the annual usage rate of 5000 hours)

Annual reduction of CO2 emission: appr. 29,700.- tons (based on the annual usage rate of 5000 hours)

Annual increase of power generation: 40 million KWh (based on the annual usage rate of 5000 hours)

Payback period of investment: 2~3 years.