TRT/BPRT is a system device for recovering the gas pressure from blast furnace, which does not change the chemical composition of the gas and does not affect the follow-up use. Transformation of the energy can be used to generate electricity or drive other energy consumption equipment. It uses aero-engine turbo technology.

Advantage of TRT

No fuel is consumed and no environmental pollution is generated in the power generation process of the device;

The quality of the original blast furnace gas is not changed;

Replacing the pressure reducing valve set provided by the blast furnace to reduce the pressure of the blast furnace gas, the pressure reducing valve set serves as a backup to reduce noise, purify the gas and improve the operation environment of the blast furnace;

The power generation cost is low and the economic benefit is remarkable.

Advantage of BPRT

The installation of BPRT unit can not only recover the pressure energy and heat energy possessed by the top gas of the blast furnace, reduce the flow noise of the gas transmission pipe network, but also carry out high intelligent control on the top pressure of the blast furnace, axial flow fan and gas turbine, thus improving the smelting intensity and output of the blast furnace. The use of BPRT system not only recovers the energy wasted in the pressure reducing valve group in the past, but also can reduce the waste discharge and further improve the energy utilization rate.

Besides supply of the whole newly-designed TRT/BPRT system, we are also focusing on the retrofit of the aging TRT/BPRT.

As to the retrofit of TRT/BPRTs, we provide domestic and international steel factories with turn-key solutions of optimized TRT flow path, bringing aerodynamically and mechanically significant improvements. With these improvements the customer can benefit from the increased TRT efficiency (obviously decreased electricity cost) and extended lifetime of rotor and blades (obviously decreased cost for maintenance and spare parts).

Our turn-key solution for TRT retrofit includes design, manufacturing, on-site installation, inspection, maintenance and spare parts service. Scope of retrofit includes machine components of rotor, stator blades and rotor blades. The turbine housing as well as the control and driving system of variable stator blades remain unchanged.

TRT is one of our products。 Besides the supply of TRT equipment, we also supply:

Axial Compressor,

Axial Fan Station,

High-Efficiency Flue Gas Turbine,

Waste Heat Recovery Turbine,

Coke Dry Quenching Circulating Blower,

Carbon Black Production Equipment and Pressure Vessel,

High Speed Centrifugal Blower, Compressor and TRT Combination,

Mechanical Vapor Recompression.

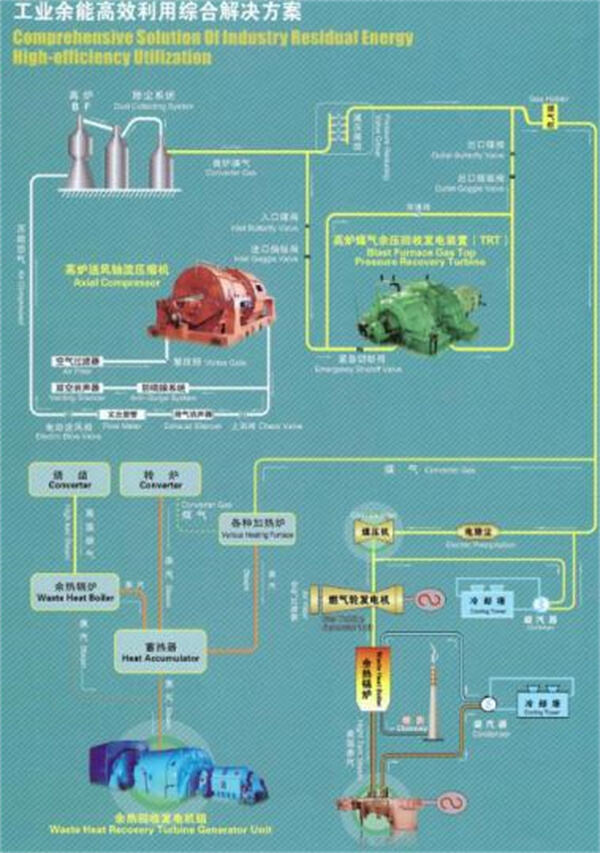

We have a comprehensive solution of industry residual energy high-efficiency utilization for iron and steel industry, petrochemical Industry and etc. Our purpose is to help customer to,improve the efficiency of energy recovery andreduce operating cost, reduce construction investment.

Flue gas turbine is a kind of secondary energy recovery device which converts the thermal and pressure energy in regeneration flue gas of catalytic cracking unit into mechanical energy by expansion work. The converted energy can be used for generating power or driving other energy consuming equipment. It is important energy saving technology in petrochemical industry. In the early 1980s, our company began to participate in the flue gas turbine development and manufacturing. After many years of technology accumulating, we’ve mastered manufacturing process and technology of the core components of flue gas turbine. Years of user’s experiences, advanced 3D design and virtual assembly technology, greatly improves the quality and accuracy of design, and provides model for the finite element analysis. So far, we are still one of enterprise who manufactured the most core components of flue gas turbine such as impeller and blade in the world. At present, we have developed more than 20 types of CFT series flue gas turbines. The output power range is from 3,000kW to 38,000kW, which can meet the requirements of all the catalytic cracking energy recovery systems in petrochemical industry.