1000MW FK Series High Pressure Boiler Feed Water Pump

The overall structure of the feed water pump adopts the structure of a double-shell barrel core-pulling pump. The feed water pump of this structure has high reliability, few leakage points, convenient installation, maintenance, disassembly and assembly, and simplicity.

1. The design of horizontal and double-shell integral core package and the large end cover integrated with the core package facilitate the integral assembly and disassembly of the core package and can realize the shortest shutdown overhaul time;

2. Rigid rotor, compact structure greatly shortens bearing span, small static deflection of rotor, low L/D ratio and high reliability;

3. The inner hole of the sealing ring with parallel throttling grooves not only maintains the hydraulic rigidity of the smooth bushing, but also increases throttling resistance, effectively preventing abrasion and occlusion;

4. Pure balance drum structure completely eliminates the possibility of axial contact between static and dynamic parts;

5. The special structure at the inlet of the throttling bush of the balancing drum effectively reduces the damage of vortex to the pump, greatly improves the static rigidity of the fluid in the gap, and at the same time, the inner hole with the reverse spiral groove is processed to minimize leakage;

6. Four-oil wedge bearing has better anti-vibration capability; Large size thrust bearing can bear overload load.

7. The impeller and balance drum equipped with hot sleeve are adopted to eliminate the leakage of liquid between the shaft and the two.

Speed: 5366 r/min

Best efficiency point efficiency: 86%

Optimal efficiency point flow: 1846 t/h

Head of the best efficiency point: 3420 m

Flow range: 1200-2200 t/h

Head range: 4200-2360 m

FT Series High Pressure Boiler Feed Water Pump

FT series feedwater pumps are mainly equipped with 600MW turbo-generator units for starting pumps and gas turbine generator units.

The overall structure of the feed water pump adopts the structure of a double-shell barrel core-pulling pump. The feed water pump of this structure has high reliability, few leakage points, convenient installation, maintenance, disassembly and assembly, and simplicity.

1. Horizontal, horizontal and segmental structure.

2. The pump casing includes inlet section, outlet section and middle section (sealed by applying a certain pre-tightening force by 8 threaded rod bolts).

3. hydraulic tools is adopted for pre-tightening of bolts, which is fast and simple.

4. The inlet and outlet pipes are all connected by flanges.

5. Various shaft end seals.

6. Excellent rotor design.

7. Advanced casting technology and structural design.

8. Convenient equipment.

Typical Technical Parameters of FT Series Feed Pump

| Model | ImpellerNo.X | Inlet dia.(mm) | Outlet dia.(mm) | Flow(m3/h) | Single-stage head (m) | Speed(r/min) | Efficiency(%) |

| FTXG34 | 4——11 | 250 | 175 | 300 | 140 | 2985 | >80 |

| FTXK40 | 4——8 | 250 | 175 | 400 | 210 | 2985 | >78 |

| FTXY36 | 4——9 | 300 | 175 | 440 | 165 | 2985 | >79 |

| FTXS39 | 6——10 | 300 | 250 | 600 | 211 | 2985 | >78 |

| FTXE39 | 4——8 | 300 | 250 | 700 | 168 | 2985 | >80 |

FK series feedwater pumps are mainly matched with 600MW and 300MW turbo-generator units in thermal power stations. It can also be matched with a gas turbine generator set.

1. Horizontal and double-shell integral core package design, and integral large end cover integrated with core package;

2. High efficiency while maintaining high reliability;

3. Reasonable radial clearance is based on high efficiency, critical speed and shaft deflection standard of the pump.

4. The rigid rotor ensures that the pump can run briefly in a partially vaporized state.

5. The critical rotating speed of the rotor is always over 120% of the maximum running speed of the pump.

6. The inner hole of the sealing ring with shallow parallel throttling grooves not only maintains the hydraulic rigidity of the smooth bushing, but also increases throttling resistance, effectively preventing abrasion and occlusion;

7. The single balance drum structure completely eliminates the possibility of axial contact between rotor and stator.

8. The special structure at the inlet of the throttling bush of the balancing drum effectively reduces the damage of vortex to the pump, greatly improves the static rigidity of the liquid in the gap, and at the same time, the inner hole with shallow parallel grooves is machined to greatly reduce leakage.

9. thicker shaft diameter, rotor static deflection is small, better rigidity;

10. The standard axial torsional shear stress is conservative and does not exceed 60 N/mm2.

11. wide fillet transition (radius r > 2.5 mm) is adopted for the diameter change of the main shaft. The minimum fillet of the keyway ensures a maximum stress concentration factor of 3.0.

12. Large-sized thrust bearings and cylindrical radial bearings with small ratio of length to diameter have safe and reliable operation and convenient maintenance.

13, according to the needs of users and adopt booster impeller;

14. Labyrinth seal with reliable operation has no static and dynamic contact, and its design life is at least 6 years (user can select mechanical seal);

15. For the integral core package convenient for maintenance, the 360-degree bearing box is directly connected with the inlet end cover and the large end cover, thus reducing the assembly error and improving the anti-vibration capability.

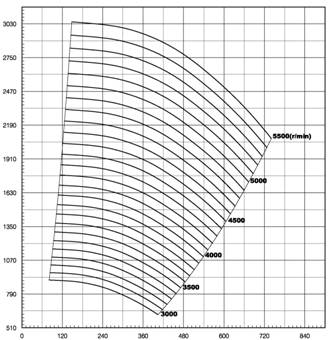

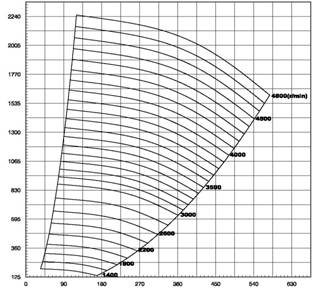

Performance Curve of FK4E39 Feed Water Pump at Various Rotations.

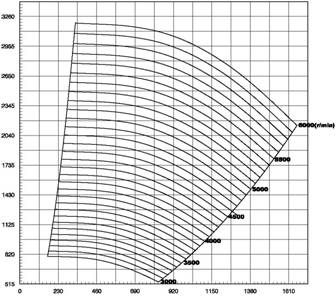

Performance curves of FK6D32 feed water pump at various rotating speeds.

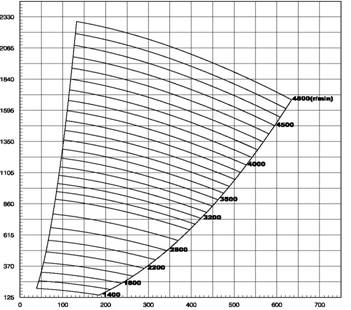

Performance curves of FK5G32 feed water pump at various rotating speeds.

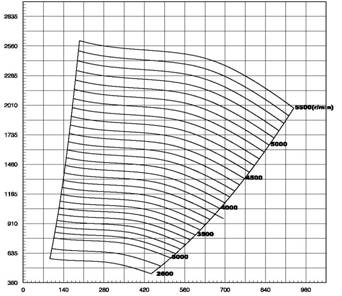

Performance Curve of FK6F32 Feed Water Pump at Various Rotations.

Performance Curve of FK6G32A Feed Water Pump at Various Rotations.