Motorostroitel JSC, N.D Kuznetsov STCS

In 1954, JSC Kuznetsov jump-started the development of the NK-12 turboprop engine (9,200 kW), which lifted the Tu-95 strategic bomber, and which today (2011) is still the world's most powerful turboprop engine. Based on this, a series of turboprop engines were developed, the world's first twin-rotor turbojet engine (22 tons of thrust) in 1958, and the most powerful turbofan engine in the mid-1980s, the NK-32 (25 tons of thrust), and more than 30 other types of aircraft, which were equipped with the Soviet Union's Chuangliu bombers, transports, and airliners, including: the Tu-195, the An-22, the Tu-95, the Tu-126, the Tu-142, the Tu-154, the Tu-142, and the Tu-145, the Tu-145, and the Tu-145. 154, Tu-114, Tu-114, An-10, Il-76, Il-62, Tu-144, Tu-22, Tu-160, Il-86, Tu-155, Tu-156, Tu-144, Il-96, Tu-204, Tu-336, Tu-338, etc. JSC Kuznetsov began production of combustion engines for driving gas transmission units in 1971, producing more than 2,700 gas engines.

In total, 1,087 units are in operation for Gazprom and foreign customers. Foreign customers include Kazakhstan, Turkmenistan, Uzbekistan, Ukraine, Belarus, Bulgaria, and Argentina. -16STM, NK-17, NK18STE, NK-36/37ST, NK38/39ST, NK-126/127.

Introduction of 6MW NK-12ST gas turbine technology

In 1969 the Council of Ministers of the USSR decided to develop the NK-12ST combustion engine for ground use to drive centrifugal compressors for pipeline gas transportation.

In 1970 the first NK-12 ST was designed on the basis of the most powerful and reliable turbojet engine based on the NK-12 turboprop engine.

In March 1971, the first test was conducted and in April 1974 it passed the national test.

Since the end of 1974, the combustion engine has operated on 24 CIS gas pipelines located in different climatic zones, as well as in Bulgaria, Poland and Argentina.

The total operating time of all NK-12STs exceeds 40 million hours. Individual engines operated for more than 120,000 hours without repair.

In total, more than 2,100 units have been produced, with approximately 1,000 NK-12 ST engines currently in operation (as of 2013)

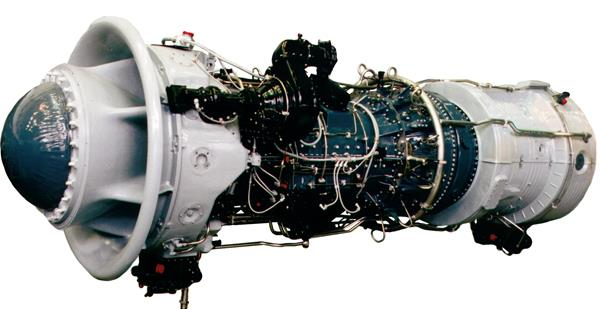

NK-12ST

Power 6.3MW.

Efficiency 26.1%.

Compressor 14 stages.

Pressure ratio 8.8.

Turbine initial temperature 941K.

Speed 8200RPM.

HPT turbine 3 stage.

PT turbine 1 stage.

Exhaust temperature 583K.

Exhaust flow 56KG/S

Introduction of 8MW NK-14ST gas turbine technology

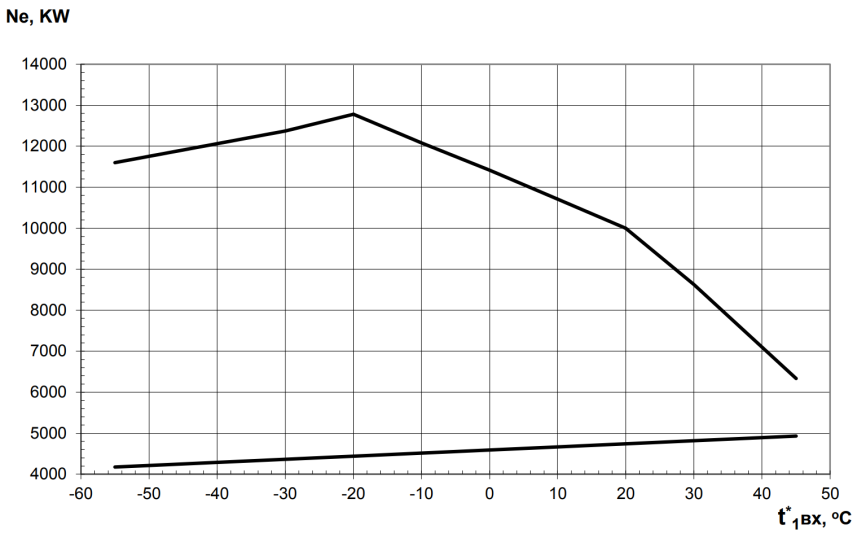

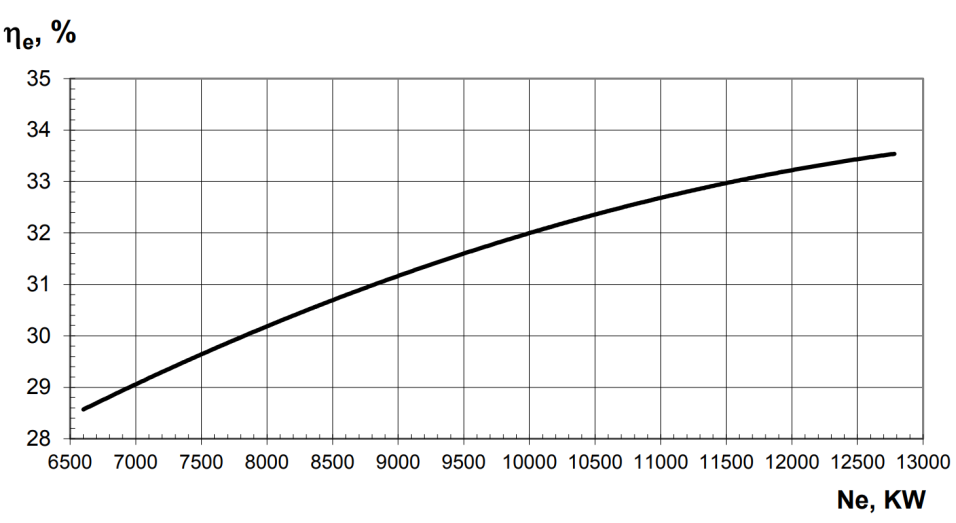

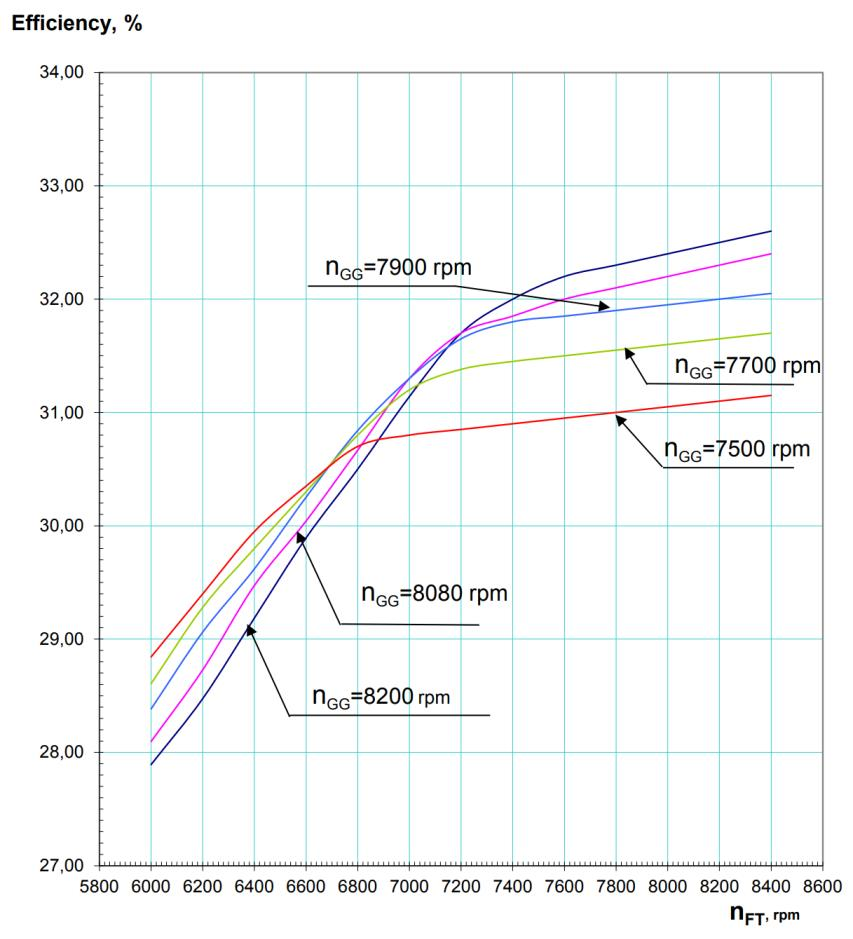

World's highest efficiency in this power class

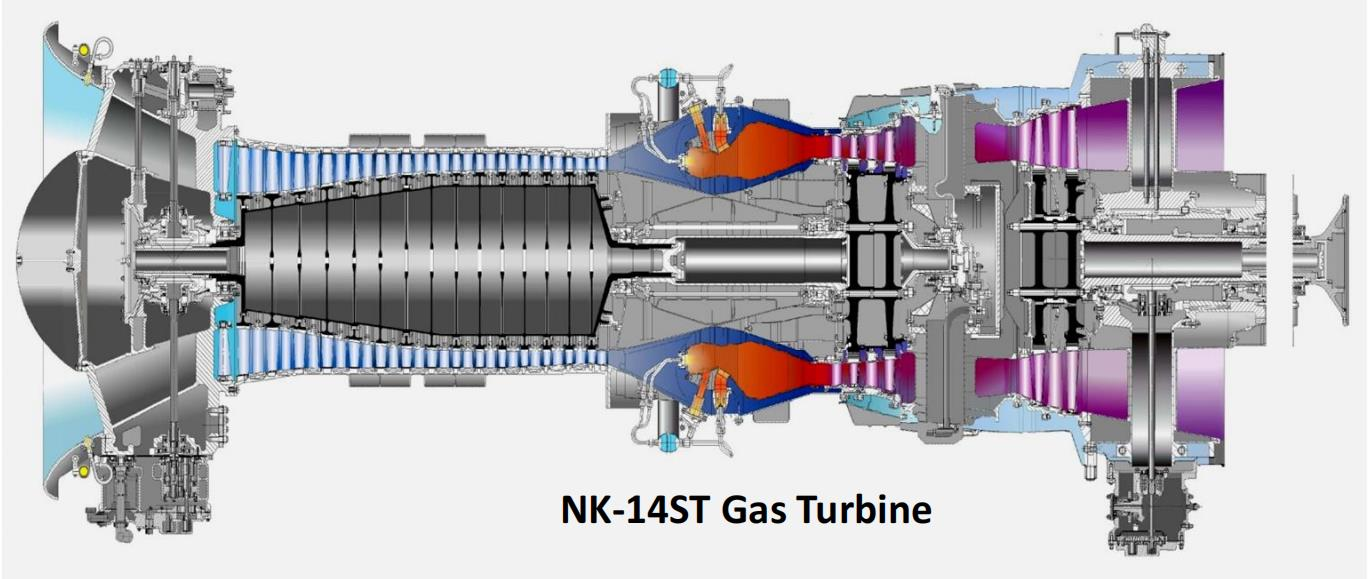

The NK-14ST engine is a further development of the improved NK-12ST with more power and higher efficiency.

Approximately 45% of the components of the basic NK-12ST are used in the NK14ST design, and the design of the corresponding flow section and turbine has been changed. The compressor turbine has had the three-stage turbine of the NK-12ST replaced by a two-stage working blade with cooling.

The is interchangeable with the NK-12ST engine on the GPA-C-6.3 gas transmission unit.

The first test of the was dated July 1992. National trials of the NK14ST engine were held in August 1995.

A total of 258 units have been produced, (as of 2013)

NK-14ST

Power 8.6MW

Efficiency 32

Compressor 14 stages

Pressure ratio 10.5

HPT speed 7800RPM

Turbine initial temperature 1280K

PT speed 8200RPM

High pressure turbine 3 stages

Power turbine 1 stage

Exhaust temperature 810K

Exhaust flow rate 37.1KG/S