Steam turbine is a kind of rotary steam power plant. High temperature and high pressure steam passes through a fixed nozzle to become accelerated airflow and then is injected onto the blades to rotate the rotor equipped with blade rows while doing work externally. Steam turbine is the main equipment of modern thermal power plant, and is also used in metallurgical industry, chemical industry and ship power equipments.

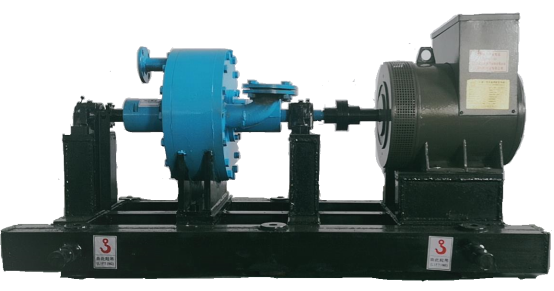

MST type steam turbine is a multi-stage steam turbine with 380 mm diameter impeller pitch circle and 1500-3000-5600-6500 rpm spindle speed. MST is a 1KW-500KW generator turbine unit that can use new steam or saturated temperature, with steam inlet pressure of only 0.15MPa and steam inlet temperature of saturated temperature. It is mainly used in the fields of energy comprehensive utilization such as ceramics, cement, power plants, chemical industry, chemical fiber, paper making, sugar making, iron and steel, waste treatment and enterprise-owned power stations, regional cogeneration, urban waste power stations, gas-steam combined cycle power generation, etc. The operation cost of the equipment is lower and the economic benefit is more remarkable. With the realization of the great rejuvenation of the Chinese nation, the "Chinese dream" and the cohesion of China's strength, the company will wholeheartedly provide first-class products and high-quality services to users and make due contributions.

2.1. Wide working range, working pressure of 0.15Mpa working pressure of 4.9Mpa.

2.2. According to the power size and user requirements, single-layer and double-layer layout structures are designed.

2.3. This series of steam turbines are also called small steam turbines. They are easy to install and can also be installed quickly. After the equipment is transported to the user's site, the unit can be directly commissioned.

2.4. The adjustment modes include electric valve adjustment and digital electro-hydraulic (DEH) adjustment, which can be used selectively. The auxiliary devices include ETS, TSI and DCS. Auxiliary devices of small units can be ignored.

2.5. The steam source can be superheated steam or saturated steam.

2.6. The impeller blades of the unit are integrated, with high safety, long service life, no damage and no maintenance. The rotor is required to be used within the operating range.

2.7. The steam inlet pressure in the sample is a standard parameter, and a special steam turbine can be designed according to the actual parameters of the user.

| Model | Capacity (kw) | Speed(r/min) | Inlet | Consumption (kg/kw.h) | Exhaust Pressure (Mpa) | Weight (t) | Overall Dimensions LxWxH(mm) | ||

| Pressure (Mpa) | Temp. (℃) | Flow (t/h) | |||||||

| N0.05-1.27 | 30-50 | 1500 | 1.27 | 300 | 0.3 | 6.2 | 0.06 | 0.33 | 506x211x621 |

| N0.07-1.27 | 50-70 | 1500 | 1.27 | 300 | 0.5 | 6.42 | 0.06 | 0.43 | 560x251x652 |

| N0.03-1.27 | 1-30 | 1500 | 1.27 | 300 | 0.2 | 6.67 | 0.06 | 0.16 | 322x211x351 |

| N0.1-1.27 | 70-100 | 1500 | 1.27 | 300 | 0.6 | 6.36 | 0.06 | 0.55 | 706x403x666 |

| NO.15-1.27 | 150 | 1500 | 1.27 | 300 | 1 | 6.35 | 0.05 | 0.62 | 735x432x701 |

| N0.2-1.27 | 200 | 1500 | 1.27 | 300 | 1.3 | 6.36 | 0.05 | 0.7 | 821x456x801 |

| N0.3-1.27 | 300 | 1500 | 1.27 | 300 | 1.9 | 6.33 | 0.05 | 0.76 | 850x475x855 |

| N0.4-1.27 | 400 | 1500 | 1.27 | 300 | 2.7 | 6.63 | 0.05 | 0.81 | 933x520x900 |

| N0.5-1.27 | 500 | 1500 | 1.27 | 300 | 3.1 | 6.25 | 0.05 | 0.88 | 988x622x956 |

| N.55-1.27 | 550 | 1500 | 1.27 | 300 | 3.7 | 6.74 | 0.05 | 0.9 | 988x635x975 |

| N0.6-1.27 | 600 | 1500 | 1.27 | 300 | 4 | 6.7 | 0.05 | 0.95 | 1010x755x1000 |

| B0.05-1.27/0.2 | 30-50 | 1500 | 1.27 | 300 | 0.8 | 26.2 | 0.2 | 0.31 | 506x211x621 |

| B0.07-1.27/0.2 | 50-70 | 1500 | 1.27 | 300 | 1.3 | 26.42 | 0.2 | 0.43 | 506x251x652 |

| B0.03-1.27/0.2 | 1-30 | 1500 | 1.27 | 300 | 0 | 26.67 | 0.2 | 0.16 | 322x211x351 |

| B0.1-1.27/0.2 | 70-100 | 1500 | 1.27 | 300 | 1.8 | 26.36 | 0.2 | 0.55 | 706x403x666 |

| B0.15-1.27/0.2 | 150 | 1500 | 1.27 | 300 | 4 | 26.35 | 0.2 | 0.62 | 735x432x701 |

| B0.2-1.27/0.2 | 200 | 1500 | 1.27 | 300 | 5.3 | 26.36 | 0.2 | 0.7 | 821x456x801 |

| B0.3-1.27/0.2 | 300 | 1500 | 1.27 | 300 | 7.9 | 26.33 | 0.2 | 0.76 | 850x475x855 |

| B0.4-1.27/0.2 | 400 | 1500 | 1.27 | 300 | 11 | 26.63 | 0.2 | 0.81 | 933x520x900 |

| B0.5-1.27/0.2 | 500 | 1500 | 1.27 | 300 | 13 | 26.25 | 0.2 | 0.88 | 988x622x956 |

| B0.55-1.27/0.2 | 550 | 1500 | 1.27 | 300 | 15 | 26.74 | 0.2 | 0.9 | 988x635x975 |

| B0.6-1.27/0.2 | 600 | 1500 | 1.27 | 300 | 16 | 26.7 | 0.2 | 0.95 | 1010x755x1000 |

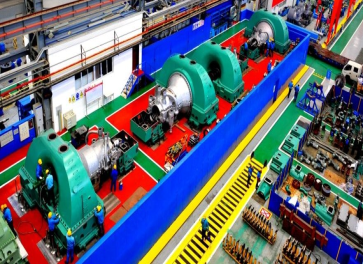

In industrial production, steam turbines are directly used as prime movers to drive some large mechanical equipment, such as large fans, feed water pump compressors and other equipment with relatively high power. Steam turbines for this purpose are called industrial steam turbines(nowadays some industrial steam turbine are also used in paper mill, sugar refinery for the purpose of generation and heat supply). Steam turbines that drive pumps, blowers, compressors and other machinery or steam turbines for power generation that are closely related to industrial production processes. Industrial steam turbines can not only use fuel or steam generated in boilers by-product heat energy in various industrial production processes, but also use residual steam in production processes.

Dongturbo's leading product, thermal power turbine, has a complete product series of various types or combinations such as condensation, air cooling and heat supply. The power and parameters of the unit have developed from 1MW high-pressure turbine to 300 MW ultra-supercritical turbine. It has mature, reliable and advanced air cooling and heat supply technologies and complete auxiliary equipment, and is in the leading position in China.